-

About Us

-

Our Business

menu close

About Us

Our Business

menu close

Apr 08, 2024

#PLIMBING

The specifications for Unplasticized poly(vinyl chloride) (PVC-U) pipe fittings for drain adhere to the JIS K 6739 standard.

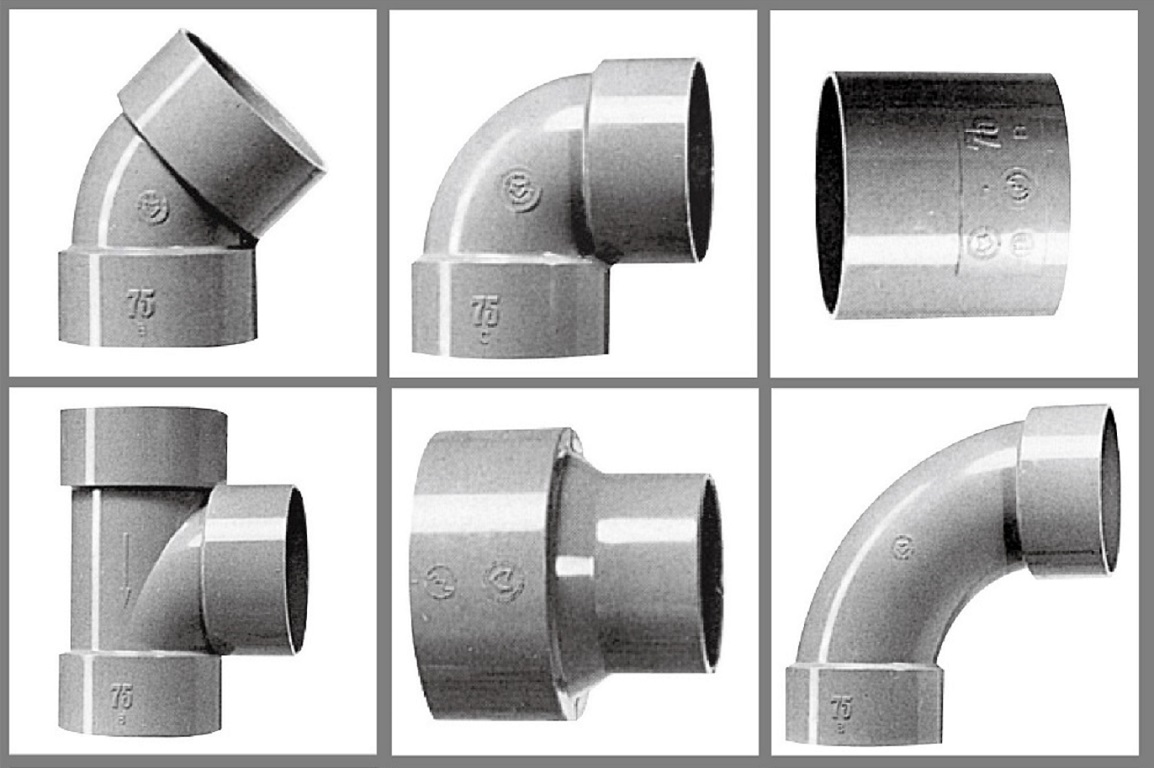

DV Fittings:

These rigid PVC drainage fittings are purpose-built to seamlessly connect with VP Pipes. They feature shorter sockets and a gradual taper. By inserting them until the socket’s stopper depth, these joints eliminate any step between the pipe and the fitting.

VU Fittings:

These standard drainage joints are tailor-made for seamless connection with VU Pipes. They maintain the same inner diameter as VU pipes. Their flat joint design ensures smooth wastewater flow, effectively preventing blockages and clogs. Since VU Fittings share the thin-walled construction of VU Pipes, the step at the joint connection remains minimal.

Remember that both DV Fittings and VU Fittings are well-suited for non-pressurized drainage systems.

The specifications for Unplasticized Poly (Vinyl Chloride) (PVC-U) pipes include both VU Pipes and VP Pipes, adhere to the JIS K 6741 standard.

VP Pipes are commonly employed in buildings for various purposes, including miscellaneous drainage, sewage, rainwater, and ventilation systems.

They have the advantage of being thicker and less prone to deformation compared to VU pipes. Additionally, their smooth inner surface results in minimal friction resistance, making it difficult for highly viscous liquids to adhere. As a result, VP pipes exhibit excellent drainage efficiency.

However, it’s essential to exercise caution when exposed to direct sunlight. Elevated surface temperatures due to sunlight can cause warping in PVC pipes, resulting from temperature differences between the pipe’s front and back surfaces.

VU Pipes, on the other hand, feature thinner walls compared to VP pipes. As a result, they are typically used in low-pressure piping systems, such as those found in regular residential houses or simple drainage facilities.

It’s important to note that even though the outer diameter (referred to as “nominal size”) of VP and VU pipes may be the same, their inner diameters differ.

Maezawa Chemical Industry Co., Ltd., a prominent supplier of PVC fittings and pipes in Japan, plays a vital role in the development, manufacturing, and distribution of products related to water supply, sewage, environmental equipment, and water treatment systems. With a wealth of experience and a track record spanning many years, they remain steadfast in their commitment to producing reliable products through their well-established technical expertise.

In 1954, they blazed a trail by pioneering the development of “rigid polyvinyl chloride (PVC) fittings for water supply.” These fittings serve as the crucial connectors between pipes that transport water all the way from household faucets.

During that era, metal pipes dominated water supply pipelines. However, their susceptibility to corrosion, weightiness, and challenging joinery posed significant drawbacks. In response, several companies introduced pipes made of resin (specifically PVC). Yet, creating suitable fittings presented a formidable technical hurdle, causing most companies to abandon the endeavor. Undeterred, Maezawa Chemical Industry persisted through trial and error, achieving the successful molding of non-plasticized fittings in Japan. This groundbreaking achievement accelerated the widespread adoption of resin-based piping systems, ushering in a new era of water infrastructure.

Recent Post